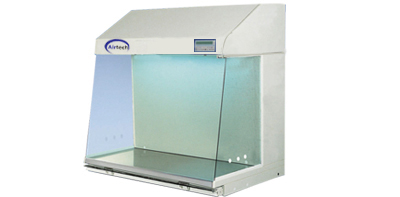

LAMINAR FLOW: Vertical Laminar Air Flow system provides operation in sterile and particle free conditions by continuous flushing of working area of unidirectional vertical and ultra filtered airflow. It assures a full product protection.

| Cleanliness | Class 100 | |

| Particle Retention | 0.3 Micron & Above |  |

| Noise Level | 65 decibel ± 5 | |

| Velocity | 90 Feet/Minute ± 20 | |

| Worktable | By melamine laminated ply or Stainless steel | |

| Front door | 6mm clear acrylic or 3mm Poly carbonat | |

| Illumination | Fluorescent tubes with diffusers. | |

| Other accessories | Manometer, Additional power point, gas inlet & Castors. | |

| Power Supply | 230V single phase, 50 Hz | |

| HEPA Filter | Media Ultra clean glass fiber paper - imported | |

| Casing | Epoxy coated CRCA frame | |

| Separators | Fine corrugated aluminum foils | |

| Retention | 0.3 Micron | |

| Efficiency | 99.97% | |

| PRE Filter | Media Synthetic, non-woven polyester fibers | |

| Casing | Enamel painted CRCA frame Retention 10 - 15 Micron | |

| Efficiency | 90 % |

Material of construction: Basic cabinet made from water proof commercial ply, with exteriors covered by industrial laminated

sheets & interiors coated with synthetic rubber paint over suitable primer base. We also supply the Laminar airflow with complete CRCA sheet metal construction with powder-coated finish.

Blower Assembly: DIDW type blower system, which consists of dynamically & statically balanced aluminum centrifugal impeller driven by an single phase, 1440-RPM motor, enclosed in an powder coated MS casing suitably suspended in a pair springs & connected to the filter chamber through flexible canvas duct.

AIRTECH offers widest range of Laminar Airflow Equipments & Systems for the Application in the field of Scientific & Industrial Research, Micro Biology & Tissue Culture, Hospitals & Medical Education, Drugs & Pharmaceutical Industries, Electronics & Space Applications, etc. Our range of equipment & systems are designed with best of its quality & performance & are accepted by various Govt. & Private sector establishments across the nation.

Technical Details |

|||

| Cleanliness | CLASS 100 |  |

|

| Particle Retention | 0.3 micron & above | ||

| Velocity | 90 FPM + 20% | ||

| Illumination | 750 - 800 lumen | ||

| Noise level | 60- 65 decibels (A) | ||

| Vibration level | 200 micron pp. | ||

| Standard | ISO 14644-1 | ||

| Power supply | 220V Single Phase | ||

AIRTECH offers Laminar Flow equipment constructed by using industrial block boards with exterior surface covered by decorative laminated sheets & inner surface coated with synthetic rubber paint. Air tight joints are ensured by using best quality adhesives.

HEPA filters made of micro clean glass fibre paper of imported origin with fine corrugated aluminium foil separators. Pressure drop will be 23 mm WG. Pre & filters are manufactured by using synthetic non woven polyester fabric material with HDPE mesh reinforcement on both sides. Both the filters are protected by suitable grill arrangement.

Blower assembly consists of a single phase,double shaft motor, directly coupled with a pair of centrifugal type aluminium impeller & enclosed within a specially designed MS casing.

Optional accessories includes Stainless steel work table in lieu of Laminated table, UV lamps, Clear acrylic front doors, Standard accessories includes power points, Pressure manometer castor wheels or leveling screws, illumination, side screens etc.

Horizontal flow model with bottom stand arrangement. This type of Laminar air flow benches are used for tissue culture applications. It provides more leg space & thereby helps to keep the surrounding clean. Vibration is reduced to a very minimum level by keeping the total work station on a heavy duty structural work. The stainless steel work table is isolated from the main unit. An optional steri-pot holder can be provided below the work table with control switch located adjacent to that.

Bio-safety cabinets are available in Stainless steel and GI with PU coated construction. Worktables are of removable type and suitable for oven baking. Inner surface are completely line with stainless steel. HEPA filters are of Minipleate type. Differential pressure is monitored through specially designed low-pressure gauges. Working chamber is provided with UV & Illumination tubes. Feather-touch control switch with indicators are provided for the operations of blower / illumination / UV Bio-safety cabinets are available with various optional Special features such as VFD controlled air-blowers for adjustable airflow, Operation of UV integrated with the front-door movement to avoid accidental exposure to UV rays, warning alarm when differential pressure exceeds the limit to indicate filter choking level, warning alarm when the front sash is opened beyond safety-level Bio-safety cabinets are available in various standard sizes and custom-built sizes to suit user’s requirement

Bio Safety Cabinet Class - IBio Safety Cabinet Class - I

Recommended for personnel & Environmental protection only

Class I Bio Safety Cabinet is defined as a totally enclosed, ventilated unit of airtight constructions. The front panel can be opened, allowing room air to enter the cabinet, sweep the inner surfaces, and exhaust-out through the duct.  A front sash with glove ports may be installed. If glove are installed, air is drawn through a secondary opening equipped with a primary filter. A laboratory hood could be considered a class I BSC, the exhausted air is passed through HEPA filter before released in to the atmosphere. The Cabinet unit is maintained under negative pressure.

A front sash with glove ports may be installed. If glove are installed, air is drawn through a secondary opening equipped with a primary filter. A laboratory hood could be considered a class I BSC, the exhausted air is passed through HEPA filter before released in to the atmosphere. The Cabinet unit is maintained under negative pressure.

Cleanliness |

Class 5 as per ISO 14644 -1 |

Air Balancing |

100% exhaust with exhaust incineration |

Particle retention |

0.3 Micron |

Bio Hazard Safety Cabinet - Class II

Recommended for Product, Personnel & Environmental protection

Class II Cabinets differ in the proportion of air re-circulated within the cabinet; velocity of airflow to the work zone; where the exhausted air is discharged. Air barrier at the work opening and the contaminated air plenum is under positive pressure. An air barrier between the operator and the work zone is maintained by a flow of room air into a full width grille in the work opening. The barrier air mixes with the laminar flow air in a sump underneath the work surface, and is exhausted to the outside environment through duct via a HEPA

Cleanliness |

Class 5 as per ISO 14644 -1 |

Air Balancing |

70% re-circulation & 30% exhaust |

Particle retention |

0.3 Micron & above |

Bio Hazard Safety Cabinet - Type A/B

Recommended for Product & Personnel protection

Class II A/B differs in the proportion of air exhausted and re-circulated within the cabinet; velocity of airflow to the work zone creates an ultra-clean environment for product protection. An air barrier between the operator and the work zone is maintained by a flow of room air into a full width grille in the work opening.  The barrier air mixes with the laminar air in a sump underneath the work surface, and is re-circulated with in the cabinet through HEPA filter.

The barrier air mixes with the laminar air in a sump underneath the work surface, and is re-circulated with in the cabinet through HEPA filter.

Class II A/B Biohazard Safety Cabinets are not recommended for use with gases or vapors. A primary application is for sterile packaging. Care is required while decontaminating the cabinet.

Cleanliness |

Class 5 as per ISO 14644 -1 |

Air Balancing |

100% re-circulation |

Particle retention |

0.3 Micron & above |

Bio Hazard Safety Cabinet : Class - II Type B1

Recommended for Product, Personnel & Environmental protection

In Class II-B1 Cabinets 30% of air re-circulated within the cabinet and the remainder exhausted outside the laboratory through optional exhaust air incinerator for environmental protection. Velocity of airflow to the work zone creates an ultra-clean environment for product protection.

Maintains a minimum measured average inflow velocity of 75 fpm through the work area access opening. The face velocity at the access opening varies between 80 fpm and 100 fpm. Have HEPA filtered down flow air from a common plenum.

Cleanliness |

Class 5 as per ISO 14644 -1 |

Air Balancing |

30% re-circulation and 70% exhaust |

Particle retention |

0.3 Micron & above |

Bio Hazard Safety Cabinet : Class - II TYPE B2

Recommended for Product, Personnel & Environmental protection

Class II Type B2 Bi cabinets are referred to as “total exhaust” cabinets because the 100% contaminated air is exhausted to the atmosphere after HEPA filtrations without re-circulating in the cabinet.

Class II Type B2 Bi cabinets are referred to as “total exhaust” cabinets because the 100% contaminated air is exhausted to the atmosphere after HEPA filtrations without re-circulating in the cabinet.

Cleanliness |

Class 5 as per ISO 14644 -1 |

Air Balancing |

100% Exhaust with incinerations |

Particle retention |

0.3 Micron |

Bio Safety Cabinet - Class III

Recommended for Personnel and Environment protection

These cabinets are totally enclosed ventilated unit of airtight construction. Operations in the cabinet are conducted through glove-ports, which are provided with rubber gloves. The Cabinet unit is maintained under negative pressure.  Supply air is drawn into the cabinet through HEPA filters. The exhaust air is treated by HEPA filtration and incinerations.This type of cabinet systems provides the means to control air borne particulates containments including micro – organisms determined to be potentially harmful to personnel the product and the environment. These cabinets provides high level of protection to the personnel and the environment

Supply air is drawn into the cabinet through HEPA filters. The exhaust air is treated by HEPA filtration and incinerations.This type of cabinet systems provides the means to control air borne particulates containments including micro – organisms determined to be potentially harmful to personnel the product and the environment. These cabinets provides high level of protection to the personnel and the environment

Cleanliness |

Class 5 as per ISO 14644 -1 |

Air Balancing |

0% re-circulation & 100% exhaust |

Particle retention |

0.3 Micron |

Specifications |

||

| Cleanliness | Class 10000 (& Class 100) |  |

| Velocity | 30 Mtr. / Sec. | |

| Lighting | By Fluorescent tubes - 2 x 20 W | |

| Shower timing | 0 To 120 Seconds - Adjustable | |

| Vibration | 200 micron PP | |

| Sound Level | 70 Db A+./- 5% | |

| Blower capacity | 1200 CFM | |

| Pressure | 75 mm WG | |

| Powered By | 2 HP, 3000 Rpm Motor. | |

| Make | KIRLOSKER / CROMPTON | |

| Power Supply | 415 V, 3 Phase | |

MATERIAL OF CONSTRUCTION

Cabinet by Water Proof Commercial Ply in Teak Wood Structure. External surface covered worth industrial laminated sheets and air plenum surface coated with synthetic rubber paint over suitable primer base.

Platform covered by aluminium grated or PVC mat flooring and door are made of 6 mm clear glass in aluminium pipe with automatic door closures & manual locks.

Pre filter made from synthetic polyester non woven fiber, particle retention 10 to 15 micron. Efficiency 90%, Pressure Drop 6 mm WG.

HEPA FILTERS are made of micro clean, glass fiber paper of imported origin, Particle Retention 0.3 Micron & above pressure drop - 23 mm WG.

CONTROLS

Motor by DOL Starter, Doors by Electromagnetic Interlocking. Overload Protection by thermal relay. Shower duration by preset electronic timer. Shower operation by push buttons. Emergency off by mushroom head push button.

Invisible dust has a telling effect on sensitive electronic equipment. It goes without saying prevention is always better than cure.

Dust prevention is no longer a luxury but a necessity in almost all spheres of life.

|

|

|||||

Positive pressure modules are designed to provide a clean area within a small enclosure or cell. These pressure module adopts the same LAMINAR AIR FLOW principle.

Pre filters are fixed at the rear end of the unit and the blower assembly used in the system sucks the air & passes to the HEPA filter chamber where the air is filtered to the maximum level.

Dimensional Details |

||

HEPA Filter size |

Media Ultra clean glass fiber paper - imported |

|

Casing |

As per Specific Requirement |

|

Particle retention |

0.3 micron |

|

Cleanliness |

CLASS 100 |

|

Overall |

CLASS 10000 |

|

Power supply |

220 V. Single phase |

|

The Basic cabinet is fabricated from pre treated industrial  block board with exteriors covered by decorative laminated sheets & interiors coated with synthetic rubber paint. Alternatively, the total construction may be of CRCA sheet metal with suitable MS structures finished by epoxy paint or powder as per requirement.

block board with exteriors covered by decorative laminated sheets & interiors coated with synthetic rubber paint. Alternatively, the total construction may be of CRCA sheet metal with suitable MS structures finished by epoxy paint or powder as per requirement.

Material of Constructions : Basic cabinet structure is made of; suitable thick, commercial ply panels both sides laminated with industrial laminated sheets. |

|

| AIRTECH offers a wide range of FUME EXHAUST HODDS to suit every specific application of the user. The hood is fabricated from; water proof commercial quality ply & block boards externally covered with industrial laminated sheets and interiors coated with epoxy paint over a suitable primer base . The inner walls of the working chamber is covered with epoxy coated asbestos or FRP or HDPE lining or as required. The working table is made of acid proof glazed tiles and provided with gas/air petcocks and additional power points, diffused fluorescent tubes. |

|

The front shutter is of shatter proof clear glass, framed in suitable wooden structure with vertically sliding facility and is connected with counter weight balancing arrangement.

The exhaust system consists of a dynamically balanced centrifugal impeller, made; of PVC/FRP, directly coupled with a TEFC industrial motor of 1440 RPM phase 415 and control led by a DOL starter with systems ranges from 500 CFM to 1250 CFM or above as it is proportional to the dimensions of the hood.

Clean air Fume exhaust hoods are provided with suitable ducting of FRP or PVC material with required diameter and length as per the site conditions.

Clean air Fume exhaust hoods are also available with full FRP construction or combination of FRP and Ply, With or without work bench. We also design and manufacture Scrubbers, Fume Extraction & Dust Collection Systems.

Powder Containment booths are used to control the hazardous emissions of powder dust during powder dispensing/sampling processes with out any risk to the operator and product as well protecting the environment. The down draught of HEPA filtered air prevents airborne dusts caused by handling operation away from the operator breathing zone. The air forced downwards is extracted at low level into the booth's filteration system, where dust particles are contained at three level of filteration prior to being circulated back in to the booths air stream.

| Type | Front Open | |

| Direction of flow | Vertical | |

| Material of Construction | S.S 304 / S.S 316 or CRCA Powder Coated |   |

| Cleanliness | Class 100 as per US FED STD 209E | |

| Particle Retention | 0.3 micron & above | |

| Noise Level | 65 dB on On Scale 'A' ± 5 | |

| Velocity | 90 FPM ± 20 % | |

| Illumination | Fluorescent tubes diffusers | |

| Pressure Differential | 0-25 mm inclined Manometers / Magnehelic Gauge | |

| Power Supply | 230 V single Phase , 50 Hz | |

| Pre-Filters | 10 - 15 micron rating,3- Layers of HDPE mesh, 6mm Pressure Drop | |

| Intermediate Filters | 3 micron & above,two layers of HDPE woven mesh and one layer of Non-woven polyester Bondex Media, 9 mm Pressure Drop, Efficiency 97% | |

| Supply HEPA Filters | 99.97% efficiency @ 0.3 micron rating | |

| Exhaust HEPA Filters | 99.97% efficiency @ 0.3 micron rating | |

| Blower Assembly | Statically & Dynamically balanced DIDW type blower system |

Special Features

Also called clean air tent, these units serves the purpose of relatively a smaller clean room and are available in a ready to assemble configurations. These units can be moved from place to place & finds extensive applications in the areas of automatic filling stations & packing sections of a pharmaceutical industry, assembling sections in the electronic industries, post operative patient care in hospitals and many other places here the product safety and processing, demands a high level of cleanliness around and where the process activity does not emit any level of contaminants into the local atmosphere.

Clean air tents are generally used within a CLASS 10000 clean rooms, in which a specific area where the manufacturing & processing activity is taking place. The entire ceiling is provided with HEPA filters and at least 600 air change per hour is maintained to provide an absolutely clean & CLASS 100 condition inside within minutes after the system is switched on. This type of clean air tents are fabricated in various sizes to accommodate the requirement of the site conditions.The complete structure is made of heavy duty ERW square tabular sections. The strong castors with brake, provided at the bottom enables the total unit to move from place to place. These types of work stations are useful for small volume filling of the vials and in convey or type filling sealing machines and in bottling & sealing of IV fluids etc., in the pharmaceutical industries and in the manufacturing of medical gloves & instruments etc.

Air tents,work station also called Clean Air tent, these units serves the purpose of relatively a smaller clean room and are available in a ready to assemble configurations. These units van be moved from place to place & finds extensive applications in the areas of automatic filling stations & packing sections of a pharmaceutical industry.

The pre-fabricated Vertical Flow Laminar Air Modules are available in different sizes and in different materials of construction to suit wide range of industrial applications which demands very hygienic and clean environment for any specific process activity

Provides CLASS 100 clean air flow for any specific applications such as for production machinery, filling line, packing, sealing in pharmaceutical industry, micro-electronics, food processing, space application etc

Air tents, are using at hospitals and operation theatres mostly used in kidney transplantation, Orthopeadics operations.

Provided with or without strip / plain curtains - made of clear PVC flexible screen

|

Pass through box is designed to minimize traffic and contamination entry into the clean room.

Enables parts, tools and other work items to be passed to and from the room.

Unit acts as an air lock device preventing ambient air from entering, or clean air from exiting the clean room.

| Standard features includes

|

|

|

Worktable made of polished stainless steel or melamine laminated ply door made od clear acrylic and provided with see- through window

| UV lamp | 1 no, 30 watt |  |

| Fluorscent tube | 1 no, 20 watt | |

| Gas cock | 1no | |

| Front door | clear acrylic - double folded type |

| uv chamber | ||

|