Air Cleanable Type

Non Woven Polyester Media with Aluminium expanded mesh reinforcement on both sides of the media

Pleated media for enhanced air handling capacity & lesser pressure drop

Most suitable as a pre filter for LAF cabinets, clean room return air filters and air handling unit pre filters

Synthetic adhesives to bond media to frame

Cleanable with compressed air

General Specifications

Air Tech make Pre filters are available in all sizes

Non-standard sizes can also be manufactured as per specific customer requirements

The filter frame can be fabricated with / without flange as per customer requirements

Protective screen or perforated sheet can be provided on specific requests

Available in casing thickness from 0.5 mm to 1.5 mm in variants of Mild steel/Galvanized steel/Aluminium/Stainless steel with a surface finish of enamel painted or powder coated finish or without any surface finish also

For LAF Benches

Non Woven Polyester Media with Aluminium expanded mesh reinforcement on both sides of the media

Pleated media for enhanced air handling capacity & lesser pressure drop

Most suitable as a pre filter for LAF cabinets, clean room return air filters and air handling unit pre filters

Synthetic adhesives to bond media to frame

Cleanable with compressed air

General Specifications

Air Tech make Pre filters are available in all sizes

Non-standard sizes can also be manufactured as per specific customer requirements

The filter frame can be fabricated with / without flange as per customer requirements

Protective screen or perforated sheet can be provided on specific requests

Available in casing thickness from 0.5 mm to 1.5 mm in variants of Mild steel/Galvanized steel/Aluminium/Stainless steel with a surface finish of enamel painted or powder coated finish or without any surface finish also

Water Washable Type

Available with an efficiency of 90% down to 20 microns to 10 microns as per IS 7613 test dust No.3

Several layers of High density poly ethylene(HDPE) mesh stitched together with an aluminium expanded metal layer reinforcement in between the High density poly ethylene(HDPE) mesh layers

Pleated media for enhanced air handling capacity & lesser pressure drop

Suitable as a pre-filter for comfort air handling units

Water insolvable sealants for bonding media with frame

Fully water washable

General Specifications

Air Tech make Pre filters are available in all sizes

Non-standard sizes can also be manufactured as per specific customer requirements

The filter frame can be fabricated with / without flange as per customer requirements

Protective screen or perforated sheet can be provided on specific requests

Available in casing thickness from 0.5 mm to 1.5 mm in variants of Mild steel/Galvanized steel/Aluminium/Stainless steel with a surface finish of enamel painted or powder coated finish or without any surface finish also

Metallic Viscous Filter

Available at 90% down to 20 microns

A combination of flat & corrugated layers of metallic mesh

Available with GI / Brass / Aluminium / SS meshes

Fineness of the mesh increases towards the air leaving side.

Suitable as a paint booth exhaust and kitchen hood exhaust filter

To be used in series with a louver filter attached to it to obtain good life of the filter.

General Specifications

Air Tech make Pre filters are available in all sizes

Non-standard sizes can also be manufactured as per specific customer requirements

The filter frame can be fabricated with / without flange as per customer requirements

Protective screen or perforated sheet can be provided on specific requests

Available in casing thickness from 0.5 mm to 1.5 mm in variants of Mild steel/Galvanized steel/Aluminium/Stainless steel with a surface finish of enamel painted or powder coated finish or without any surface finish also

Non-standard sizes can also be manufactured as per specific customer requirements

The filter frame can be fabricated with / without flange as per customer requirements

Protective screen or perforated sheet can be provided on specific requests

Available in casing thickness from 0.5 mm to 1.5 mm in variants of Mild steel/Galvanized steel/Aluminium/Stainless steel with a surface finish of enamel painted or powder coated finish or without any surface finish also

The filter can be assembled with / without flanges

Available in casing thickness from 1 to 1.5 mm in variants of Mild steel / Galvanized steel / Aluminium / Stainless steel

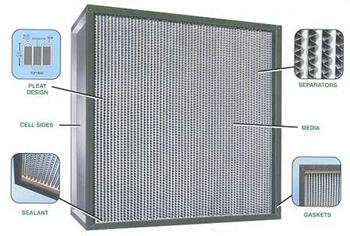

Powder coating is the standard surface finishing offered Mini-pleat HEPA FIlters

Filtration media is all glass, micro fibre, fire retardant HEPA filtration media manufactured by M/s.Lydall Inc, USA

Aluminium separators made from 0.04 mm thick aluminium foil in the case of deep pleat version.

High impact poly styrene separators in the case of mini pleat version

Synthetic soft rubber gasket with dovetail joints.

Epoxy & Silicon Sealants

Initial pressure drop of 18 mm WC for deep pleat filters and 14 mm WC for mini pleat filters

Suitability to class 100 clean rooms and work stations as per FED:STD:209E

Efficiency 99.98% down to 0.3 microns. Suitable for H13 class as per EN779

All filters are particle counted and DOP leak tested

Filter construction as per recommendations of IES-RP-001

Each filter is accompanied by a test certificate

APPLICATIONS |

|

| Clean rooms for micro component electronic manufacture & assembly |  |

| Pharmaceutical Processing | |

| Aerospace Engineering | |

| Genetic & Biological research | |

| Biohazard Atmosphere | |

| Laminar Flow Workstations | |

| Bio Safe Hoods(Biological Safety Cabinets) | |

| Hospital Operating Theaters & Intensive care units | |

| Atomic Research | |

| Pre filter stage to ULPA systems |

HEPA filters are available in all sizes in the deep pleat version.

Non-Standard sizes can also be manufactured as per specific customer requirements.

The filter can be assembled with / without flanges

Available in casing thickness from 1 to 1.5 mm in variants of Mild steel/Galvanized steel/Aluminium/Stainless steel

Powder coating is the standard surface finishing offered

Filtration media is all glass, micro fibre, fire retardant HEPA filtration media manufactured by M/s.Lydall Inc, USA.

Aluminium separators made from 0.04 mm thick aluminium foil in the case of deep pleat version.

High impact poly styrene separators in the case of mini pleat version

Synthetic soft rubber gasket with dovetail joints.

Epoxy & Silicon Sealants

Initial pressure drop of 18 mm WC for deep pleat filters and 14 mm WC for mini pleat filters

Suitability to class 100 clean rooms and work stations as per FED:STD:209E

Efficiency 99.98% down to 0.3 microns. Suitable for H13 class as per EN779

All filters are particle counted and DOP leak tested

Filter construction as per recommendations of IES-RP-001

Each filter is accompanied by a test certificate

APPLICATIONS |

|

| Clean rooms for micro component electronic manufacture & assembly |  |

| Pharmaceutical Processing | |

| Aerospace Engineering | |

| Genetic & Biological research | |

| Biohazard Atmosphere | |

| Laminar Flow Workstations | |

| Bio Safe Hoods(Biological Safety Cabinets) | |

| Hospital Operating Theaters & Intensive care units | |

| Atomic Research | |

| Pre filter stage to ULPA systems |

| Imported ULPA filter with the efficiency of 99.9999% will be supplied as per requirements Suitable for class 10 applications |  |

|

|

||

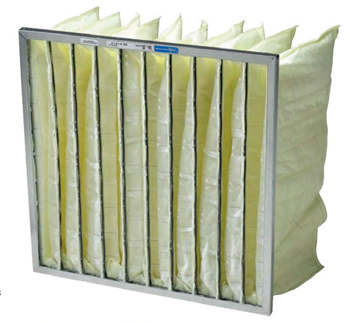

Also called as Micro filters or Rigid bag filters

Air Tech make fine filters are available in all sizes

Non-Standard sizes can also be manufactured as per specific customer requirements

The filter casing can be fabricated with/without flange as per customer requirements

Available in casing thickness from 0.75 mm to 1.5 mm in variants of Mild

steel/Galvanized steel/Aluminium/Stainless steel with a surface finish of enamel

painted or powder coated finish

Non-Woven Polyester fibres chemically bonded treated to prevent fibre disintegration and carry over is used as filtration media.

Other types of filtration media are available on specific request

3/8" Ø Al pipes as media pleat supports

6 Pleats per running foot

Synthetic adhesives to seal frame with media. Epoxy sealants are available as an option.

Initial pressure drop of 6-8 mm WC

Filtration efficiency of 99% down to 5 micron as per IS7613 test dust no2.

Suitable for EU5 & EU6 operation as per DIN24185 or F5 and F6 as per EN779

Cleanable with compressed air or high speed blower

APPLICATIONS |

||

Pharma processing units |

Chemical & Fertilizers Plants |

Hospitals - Operating Rooms & ICU's |

Main Frame Computer Installations |

Paint Booths |

Cement Factories |

Film Processing Labs |

Pre filter to Hepa Systems |

Mushroom Farms |

|

|

|

|

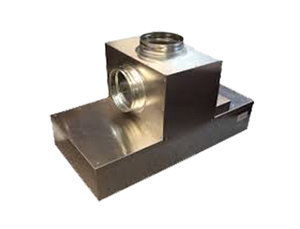

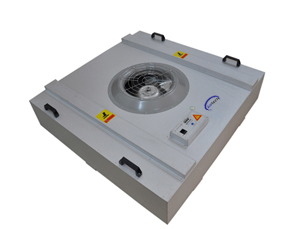

A fan filter unit (FFU) is a type of motorized air filtering equipment. It is used to supply purified air to cleanrooms, laboratories, medical facilities or microenvironments by removing harmful airborne particles from recirculating air The units are installed within the system's ceiling or floor grid.  Large cleanrooms require a proportionally large number of FFUs, which in some cases may range from several hundred to several thousand. Units often contain their own pre-filter, HEPA filter and internally controllable fan air distribution.

Large cleanrooms require a proportionally large number of FFUs, which in some cases may range from several hundred to several thousand. Units often contain their own pre-filter, HEPA filter and internally controllable fan air distribution.

Design

FFUs are typically manufactured in 4' x 2', 3' x 2', or 2' x 2' steel housings, which can be placed in ceiling grid bays of similar dimensions Units often contain a pre-filter as well as a HEPA (high-efficiency particulate air), ULPA (ultra-low particulate air) or other MERV (minimum efficiency reporting value) filter. A motorized fan is used to pull air through the filters for distribution to rooms or enclosed work stations such as hoodsFan speed is typically controlled via a step-wise or rheostat motor adjustmentDesired cleanliness levels determine the filter used: HEPA filters remove particles 0.3 um or larger at 99.99% efficiency, while ULPA filters remove particles 0.12 um or larger at 99.999% efficiency FFUs are engineered for laminar air flow, as is required in critical environments. Controlled air flowing in a uniform direction and speed (carrying microparticles) is cleaner than turbulent air that flows in multiple directions or at inconsistent speeds. Eddies created by turbulent air cause contaminating microparticles to settle on clean surfaces.

A motorized fan is used to pull air through the filters for distribution to rooms or enclosed work stations such as hoodsFan speed is typically controlled via a step-wise or rheostat motor adjustmentDesired cleanliness levels determine the filter used: HEPA filters remove particles 0.3 um or larger at 99.99% efficiency, while ULPA filters remove particles 0.12 um or larger at 99.999% efficiency FFUs are engineered for laminar air flow, as is required in critical environments. Controlled air flowing in a uniform direction and speed (carrying microparticles) is cleaner than turbulent air that flows in multiple directions or at inconsistent speeds. Eddies created by turbulent air cause contaminating microparticles to settle on clean surfaces.

Uses

4' x 2' or 2' x 2' FFUS are designed to be placed in ceiling grid bays with similar dimensions. Ceiling grids with standard size bays that match FFU dimensions are used to construct cleanrooms. Depending on the cleanliness requirements of the controlled space, more fan filter units can be added to the grid in order to meet ISO standards for airflow velocity and air changes per hour. FFUs can be used in place of a more conventional recirculating air unit such as a ducted or plenum air system. As FFUs require space above the ceiling grid (13" for the FFU module plus another 1–2 feet of "empty" air-filled space), plenums are commonly used for clean rooms with height restrictions; they are the only air systems that work in layouts with smaller internal floor dimensions Additionally, when less than 20 filters are installed in a room, a fan- powered HEPA, FFU is generally considered to be less expensive than a more conventional ducted supply system. When a microenvironment of clean air is required, FFUs can be used to construct enclosed work spaces, or laminar flow cabinets. Applying the same principle as the larger cleanroom grid, FFUs can be placed directly in a free- standing grid above the space that requires clean air. In fact, this approach is also used for silicon wafer etching in the semiconductor industry.

FFUs can be used in place of a more conventional recirculating air unit such as a ducted or plenum air system. FFUs are often used because of height restrictions in the space; they are the only systems that work in setups with smaller internal floor dimensions. Additionally when less than 20 filters are involved, a fan powered HEPA, FFU design is generally considered to be less expensive than a more conventional ducted supply system.

Also called clean air tent, these units serves the purpose of relatively a smaller clean room and are available in a ready to assemble configurations. These units can be moved from place to place & finds extensive applications in the areas of automatic filling stations & packing sections of a pharmaceutical industry, assembling sections in the electronic industries, post operative patient care in hospitals and many other places here the product safety and processing, demands a high level of cleanliness around and where the process activity does not emit any level of contaminants into the local atmosphere.

Clean air tents are generally used within a CLASS 10000 clean rooms, in which a specific area where the manufacturing & processing activity is taking place. The entire ceiling is provided with HEPA filters and at least 600 air change per hour is maintained to provide an absolutely clean & CLASS 100 condition inside within minutes after the system is switched on. This type of clean air tents are fabricated in various sizes to accommodate the requirement of the site conditions.The complete structure is made of heavy duty ERW square tabular sections. The strong castors with brake, provided at the bottom enables the total unit to move from place to place. These types of work stations are useful for small volume filling of the vials and in convey or type filling sealing machines and in bottling & sealing of IV fluids etc., in the pharmaceutical industries and in the manufacturing of medical gloves & instruments etc.

Pass through box is designed to minimize traffic and contamination entry into the clean room.

Enables parts, tools and other work items to be passed to and from the room.

Unit acts as an air lock device preventing ambient air from entering, or clean air from exiting the clean room.

| Standard features includes

|

|

work station also called Clean Air tent, these units serves the purpose of relatively a smaller clean room and are available in a ready to assemble configurations. These units van be moved from place to place & finds extensive applications in the areas of automatic filling stations & packing sections of a pharmaceutical industry.

The pre-fabricated Vertical Flow Laminar Air Modules are available in different sizes and in different materials of construction to suit wide range of industrial applications which demands very hygienic and clean environment for any specific process activity

Provides CLASS 100 clean air flow for any specific applications such as for production machinery, filling line, packing, sealing in pharmaceutical industry, micro-electronics, food processing, space application etc

Air tents, are using at hospitals and operation theatres mostly used in kidney transplantation, Orthopeadics operations.

Provided with or without strip / plain curtains - made of clear PVC flexible screen

|

|

Worktable made of polished stainless steel or melamine laminated ply door made od clear acrylic and provided with see- through window

| UV lamp | 1 no, 30 watt |  |

| Fluorscent tube | 1 no, 20 watt | |

| Gas cock | 1no | |

| Front door | clear acrylic - double folded type |